NEXT LEVEL 3D-PRINTING FOR

AGILE MANUFACTURING

AGILE MANUFACTURING

TrueFormer 600

Open the Black Box of 3D printing.

| Build Volume | 600×487× 570mm |

| Chamber max. Temperature | 250 °C |

| Build Surface Max. Temperature | 250 °C |

| Extruder | Dual Direct Drive |

| Nozzle max. Temperature | 500 °C |

| Max Print Speed | 1000 mm/s |

| Material Format | Open |

| Calibration | Fully automatic |

| Over 25 integrated sensors | Fully automatic |

| 3D Laser Profiler | Precise surface measurement and inspection |

SituGuard

Real-time 3D In-Situ Monitoring inside an industrial 3D printer. With the TrueFormer 600, TRACK3D opens the black box of additive manufacturing and unleashes a new era of precision, insight, and control.

TrueFormer 600 Powered by SituGuard

Unmatched process stability and precision control.

Active Process Monitoring

Dimensional accuracy of component's form and position tolerances

Digital Twin

Simplified certification through automated process documentation

Process Optimization

Adaptive layer-by-layer parameter control for optimal print results

Why TrueFormer 600 is the answer to Industrial 3D Printing Challenges

Key capabilities that redefine additive manufacturing insight.

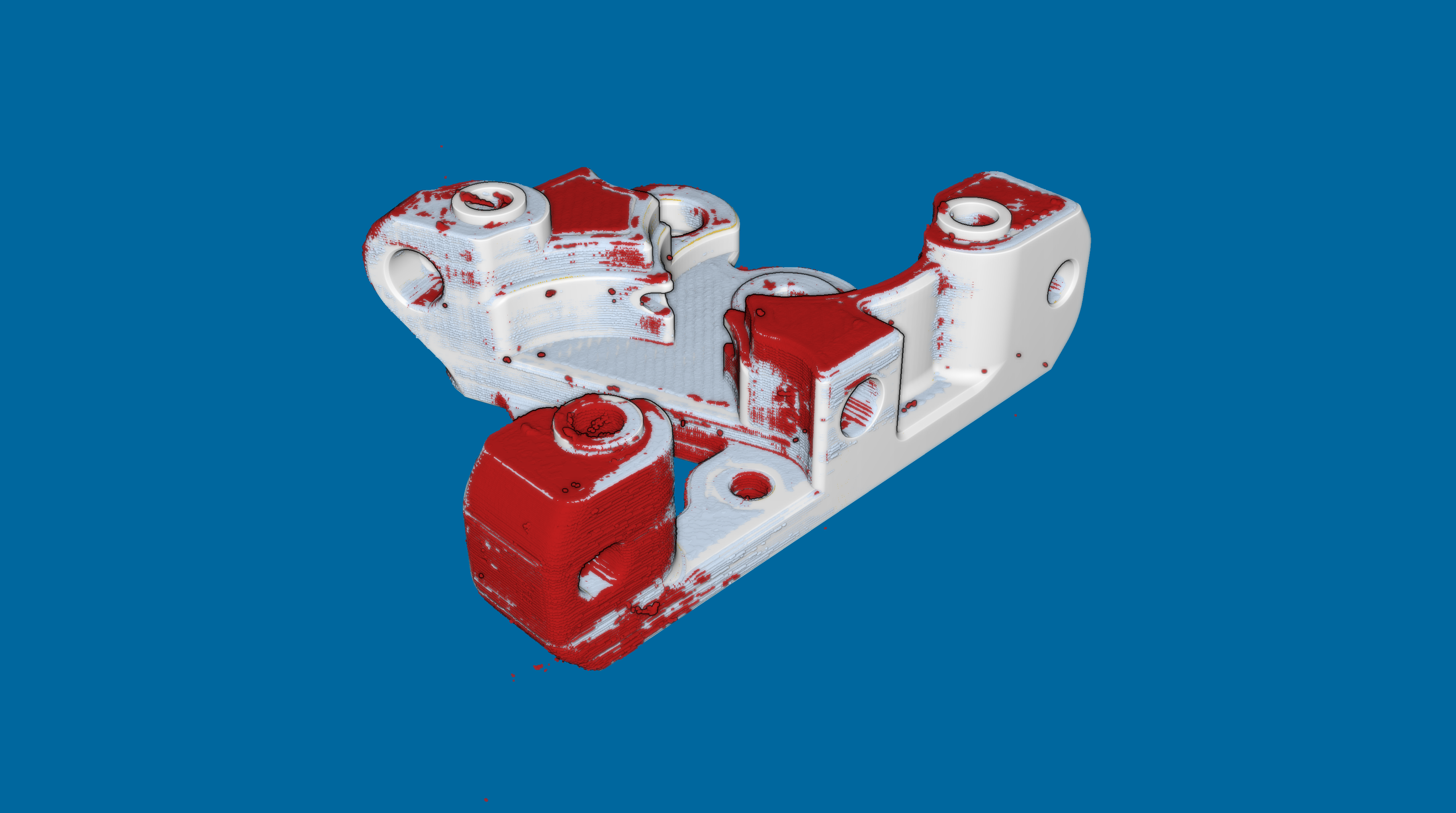

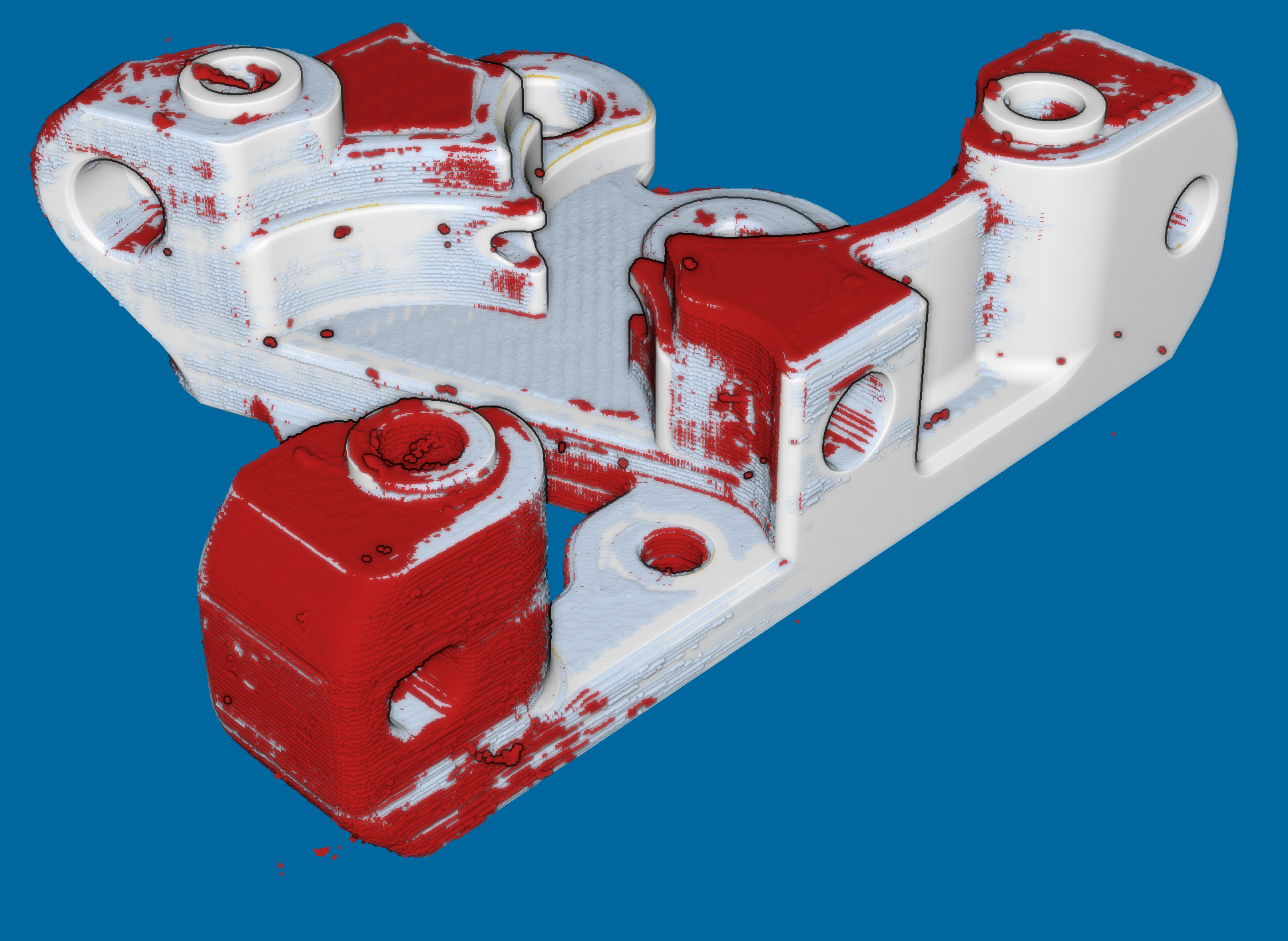

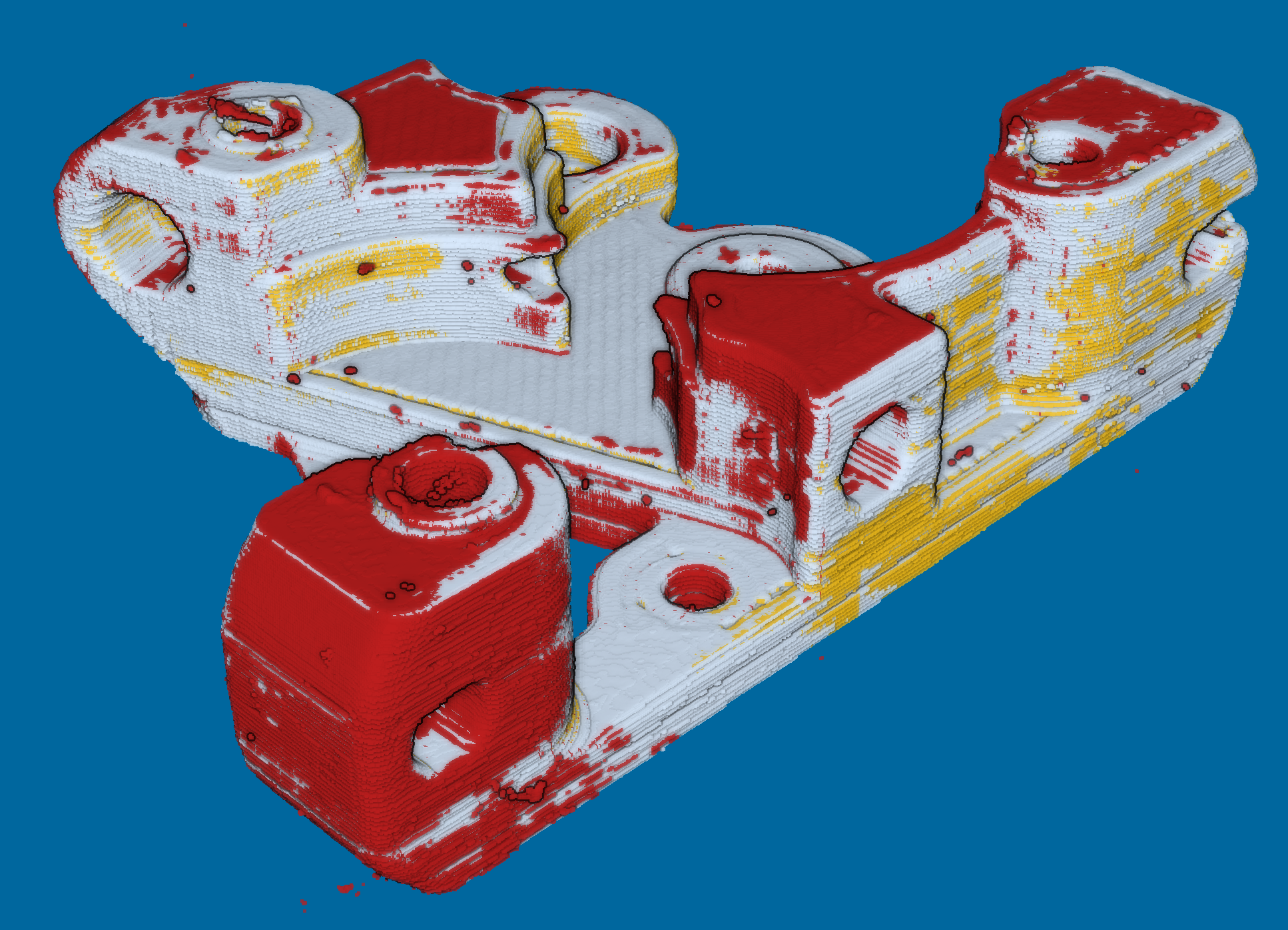

Real-Time Process Monitoring with SituGuard

SituGuard continuously monitors the entire printing process by comparing predefined target data G-code with the actual print data in real time. Through this ongoing analysis, even the smallest deviations or irregularities are immediately detected. This enables instant corrective action, ensuring consistent print quality, improved process reliability, and overall production efficiency.

As a result, the overall 3D printing process is continuously optimized, leading to significant improvements in part quality, consistency, and reliability. Over time, this ongoing enhancement ensures stable production conditions and minimizes the risk of defects or rework.

Real-Time Process Control

Every printed layer is scanned and analyzed by a profile line laser, creating a 3D point cloud of the actual geometry. → Deviations are detected and corrected immediately — not after the print is done.

Verified Quality & Full Traceability

With SituGuard, each print is documented through a digital twin, including process data, correction history, and layer validation. Industrial users get measurable, certifiable, and repeatable results.

Seamless Integration of Hardware & Intelligence

TrueFormer 600 delivers precision hardware performance. SituGuard adds process intelligence, transforming the extrusion process into a closed-loop manufacturing system that stabilizes each build and ensures repeatability.

Gefördert durch Pro FIT - Projektfinanzierung

Die TRACK3D GmbH wird im Rahmen der Pro FIT - Projektfinanzierung durch die Investitionsbank Berlin (IBB) gefördert. Ziel des Projekts ist es das innovative Closed-Loop 3D-Druckverfahren von TRACK3D im Industrie 3D-Drucker RP-600 zur Marktreife zu bringen und eine agile Serienfertigung zu ermöglichen. Co-funded by the European union